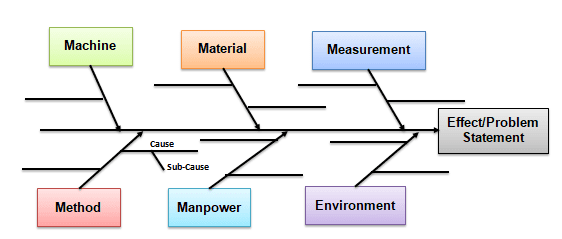

Tools that can be used in this phase are flow analysis and different root cause analysis techniques, such as the 5x Why and the Ishikawa diagram. This is the phase in which the data that is collected is used to find the root causes for the problems defined in the discovery and define phase. The control chart is visualized in the figure 3 below.Īfter the measure phase comes the ANALYZE PHASE. When the process is unstable, and acts outside these two limits, action is required in terms of analyzing the process criteria that led to this result. The control chart is a graphical visualization of the results of one metric, where a certain bandwidth of variation is allowed between an Upper Control Limit (UCL) and a Lower Control Limit (LCL). The control charts can be used to track performance on a selected metric. An example of the metric selection table is shown in figure 2. To close the loop with the previous phases of the project, a metric selection table can be created to link the metrics that were selected from the VSM to the CTQ’s from the customers defined earlier. When the VSM is done well, all important information of the process can be found in the data boxes, so the team can select the metrics based on these. The value stream mapping should help the team in defining the correct metrics to measure the success of the project. More information about capturing the current state VSM can be found in the article about value stream mapping, and more information about improving the VSM can be found in the article about the 8 steps of future state value stream mapping. An example of a very simple value stream map is shown in figure 1. In traditional lean initiatives, a current state value stream map is drawn first, after which a future state map can be designed. Data boxes make it possible to list important aspects of each process step, such as changeover times, cycle times and machine availability, which makes value stream mapping a great tool to use in (re)designing a value stream. Value stream mapping is a lean tool that can be used to map processes in detail, based on the both the flow of material and the flow of information. Tools that can be used during the measure phase are the value stream map (VSM), the metric selection table, and control charts. This phase also has three goals: gaining a detailed understanding of the process, defining what metrics can be used to measure the capability of the process, and defining a system to collect and measuring the process capabilities. The define phase is followed by the MEASURE PHASE.

This article will describe the next two phases of D2MAIC: measure and analyse.

The first article described the discovery and the define phase of the project. This is the second article on D2MAIC projects.

0 kommentar(er)

0 kommentar(er)